Mineral separation

Laboratory management

Dr. Heiko Pingel

Equipment

The mineral separation laboratory is specifically designed for the preparation and separation of mineral samples. Its equipment allows for all common workflow steps, from coarse sample preparation to the production of pure mineral concentrates for geochemical and geochronological analyses.

The equipment includes, among others:

- Crushing and sieving equipment: Jaw crusher, disc mill, vibratory disc mill, and various sieve sets for targeted grain fractionation.

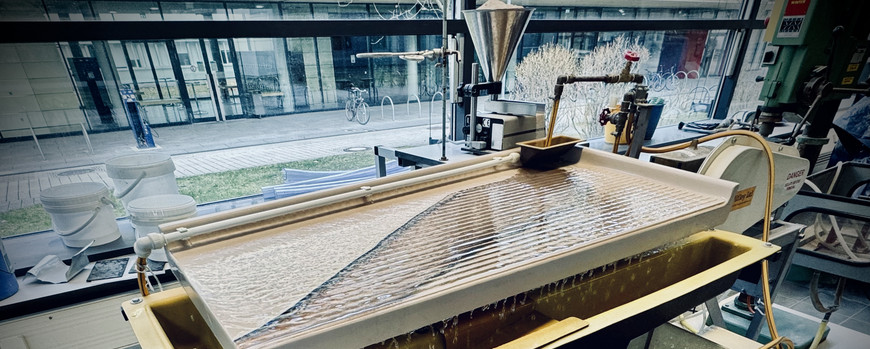

- Mechanical density separation: A Wilfley table (shaking table) for efficient separation of mineral phases based on density and grain shape, especially for the preliminary concentration of heavy minerals.

- Chemical preparation: Fume hoods and workstations for the chemical cleaning of samples (e.g., using acetic acid and hydrogen peroxide).

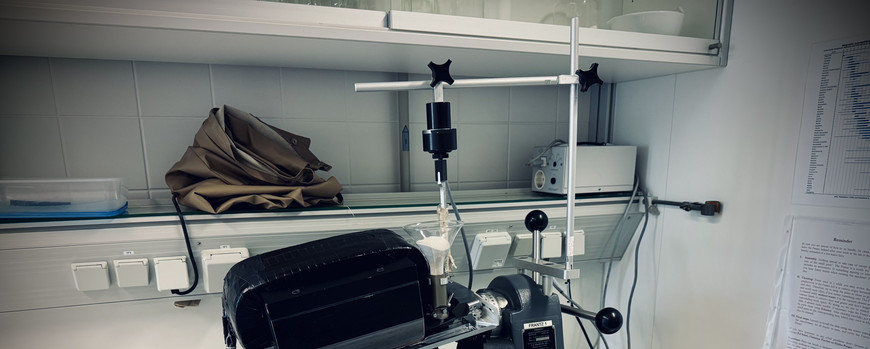

- Magnetic separation: Two isodynamic Frantz magnetic separators and hand magnets for the separation of magnetic and weakly magnetic components.

- Density separation systems: Heavy liquid separation using SPT (sodium polytungstate) and DI (diiodomethane) at various concentrations for the separation of mineral fractions by specific gravity.

- Drying and cleaning devices: Drying ovens, ultrasonic baths, and laboratory centrifuges for gentle cleaning and treatment of samples.

- Optical and manual separation: Binocular stereomicroscopes and precision needles and tweezers for manual selection of individual grains and preparation of epoxy mounts.

- Recycling: SPT, DI, and acetone are recovered using drying ovens or rotary evaporators and reused.

Lab Rules & Cleanup

General Rules

- Book all equipment via Google Calendar.

- Include your name, equipment, and time in each reservation (e.g., Frantz I/SPT - Heiko).

- Paper Lab Book: Sign in when working. Include time, equipment used, sample numbers, and your name. Record all work, even if equipment wasn’t reserved online.

- User Lists (Rooms 0.42 & 0.56): Provide name, email, and project/supervisor. Helps resolve conflicts.

- Limit reservations to 1–2 months in advance.

- Do not reserve the same equipment more than 3 days in a row.

- For work over 4 hours/day, choose start/end times to allow others access.

- Cancel reservations if you cannot use the time.

- Arrivals >1 hour late: equipment may be reassigned.

Cleanup Expectations

- Clean all equipment before and after use.

- Clean work area (tabletop and floor).

- Change vacuum filter if needed.

- Label and properly store all samples.

- Notify the lab manager if you find dirty equipment or workspace on arrival.

- Penalties: Leaving the lab dirty may result in 1–2 hours of unpaid cleaning.

Calendar Overview & Usage

Subcalendars by Room:

- Room 0.41: Hammer plate, Jaw crusher, Disk grinder

- Room 0.42: Sieves, Water Table, Shatter Box

- Room 0.56: Frantz I & II, SPT, DI

Reservation Steps:

- Select your desired time.

- Choose the correct room subcalendar (not the main “rocks2sand” calendar).

- Enter your name and equipment (e.g., Frantz I/SPT - Heiko).

- Accept the reservation.

Calendar Access:

- Hosted by: up.sampleprep@gmail.com (do not email)

- User account: rocks2sand@gmail.com (password via Heiko)

- Tip: Sync the calendar with your devices. See Google help for instructions.