Soft Matter Physics and Optoelectronics Group at University of Potsdam

What PWM is doing

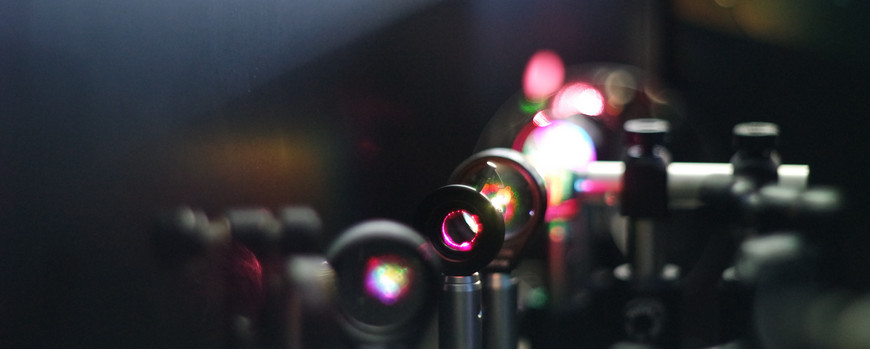

The research of the “Soft Matter Physics and Optoelectronics” group is concerned with physical processes in soft matter semiconducting layers. Our systems of interest comprise traditional soft matter materials such as organic semiconductors, but also organo-metallic perovskite semiconductors and, most recently hybrid systems based on 2D TMDcs. Our particular focus is the understanding and advancement of these systems for specific optoelectronic applications, such as photovoltaic devices and photodetectors.

At the heart of our studies is the nature and dynamics of excitations and charges in these systems. The group has therefore installed a variety of transient techniques, designed to follow the fate of these excitations in functional devices on all relevant time scales, from sub-picoseconds through steady state. The group is particularly known for our time-delayed collection field setup, which is unique with regard to temporal resolution and sensitivity, but we also make use of various all-optical techniques including steady state and time resolved fluorescence spectroscopy and femtosecond transient absorption. The results of these measurements serve as inputs for extensive drift-diffusion simulations, but also for the development of analytical models to describe the function of entire devices.

With this knowledge at hand, materials and device structures are further optimized, with the prospect to push the optoelectronic performance parameters beyond current limits.

For more details about the work from our group, welcome to check our YouTube channel: @OrganicOptoelectroShoaeeNeher

Progress in OPVs…and beyond 20% - Update

The organic solar cell (OSC) research community has made great strides in the conversion of sunlight into electricity. With the development of new materials, device architectures and processing techniques, the community is now able to produce efficient OSCs whose power conversion efficiencies exceed 20%. According to NREL, this value is quadruple of what was achievable just 20 years ago. What a feat and motivation for the OSC community in the effort to realize the potential for this technology!

As we approach more exciting research , innovation and progress in the field , we at PwM give you a collected visual of the record efficiencies over the last 3 years , reflecting on the best binary and ternary-based OSCs that were produced and certified . Here’s to more success and growth in OSC technology !

References

- Nat Energy6, 605–613 (2021). https://doi.org/10.1038/s41560-021-00820-x

- Nat. Mater.21, 656–663 (2022). https://doi.org/10.1038/s41563-022-01244-y

- Adv. Energy Mater., 12, 220250 (2022). https://doi.org/10.1002/aenm.202202503

- Adv. Mater., 35, 12, 2210760 (2023). doi.org/10.1002/adma.202210760

- Nat Commun14, 1760 (2023). https://doi.org/10.1038/s41467-023-37526-5

- Nano-Micro Lett.15, 92 (2023). https://doi.org/10.1007/s40820-023-01057-x

- Angew. Chem.Int. Ed., 62, e2023126 (2023). https://doi.org/10.1002/anie.202312630

- Angew. Chem.Int. Ed.,62, e2023130 (2023). https://doi.org/10.1002/anie.202313016

- Nano-Micro Lett.15, 241 (2023). https://doi.org/10.1007/s40820-023-01208-0

- Angew. Chem. Int. Ed, 63, e202318756 (2024). https://doi.org/10.1002/anie.202318756

- Small, 20, 2402793 (2024). https://doi.org/10.1002/smll.202402793

- J. Am. Chem.Soc.,146,12011−12019 (2024). https://doi.org/10.1021/jacs.4c01503

- Nat Commun15, 1830 (2024). doi.org/10.1038/s41467-024-46022-3

- Angew. Chem. Int. Ed., 62, e202314420 (2023). doi.org/10.1002/anie.202314420

- Joule 8, 3, 835-851 (2024). doi.org/10.1016/j.joule.2024.01.005

- Adv. Mater., 36, 2400342 (2024). doi.org/10.1002/adma.202400342

- Energy Environ. Sci., 17, 2492 (2024). https://doi.org/10.1039/D4EE00605D

- Materials Science and Engineering: R: Reports, 159, 100794 (2024). https://doi.org/10.1016/j.mser.2024.100794

- Adv. Funct. Mater., 34, 2406744 (2024). https://doi.org/10.1002/adfm.202406744

- J. Am. Chem. Soc., 146, 14287−14296 (2024). https://doi.org/10.1021/jacs.4c03917

- Adv. Mater., 36, 2406690 (2024). https://doi.org/10.1002/adma.202406690

- Nat Energy9, 975–986 (2024). https://doi.org/10.1038/s41560-024-01557-z

- Adv. Mater., 36, 2407517 (2024). https://doi.org/10.1002/adma.202407517

- Nat Commun15, 8872 (2024). https://doi.org/10.1038/s41467-024-53286-2

- Nat Commun15, 6865 (2024). https://doi.org/10.1038/s41467-024-51359-w

- Joule, 8, 11, 3153-3168 (2024). https://doi.org/10.1016/j.joule.2024.08.001

- Nat. Mat (2025). https://doi.org/10.1038/s41563-024-02087-5#