Sebastian Zimmermann and Aaron Justin Koenig test the method of photon density wave spectroscopy within the “Applied Analytical Photonics” group, which can be used to monitor chemical, physical, and biological processes in undiluted, turbid liquids on an industrial scale and in real time. Glass fibers transmit laser light through the sample, whose properties change the light intensity. Conclusions can then be drawn about the quality and composition of the sample. With the experiment that is presented here, a neutralization reaction of an acid with a base in which silicon dioxide precipitates, the measurement technology is assessed and refined in the laboratory. This method is also used in the production of nanoparticles or in algae cultivation.

- First, distilled water is heated to 80°C in a six-liter glass reactor. The required chemicals, sulfuric acid (H2SO4) and water glass (Na2SiO3), are measured and prepared.

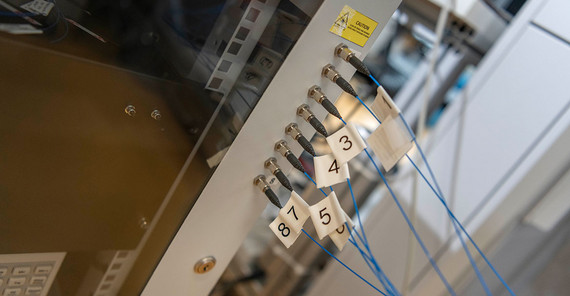

- Zimmermann connects the fiber optic cables of the measuring probe for photon density wave spectroscopy, which is in the reactor, to the spectrometer.

- Koenig places the dosing hoses in the chemical containers with sulfuric acid or water glass and attaches the pH probe to monitor the neutralization reaction in the reactor.

- The researchers take a test measurement with the probe. The immersed rods serve as laser sources in the visible and near infrared spectral range to generate photon density waves in the light-scattering solution.

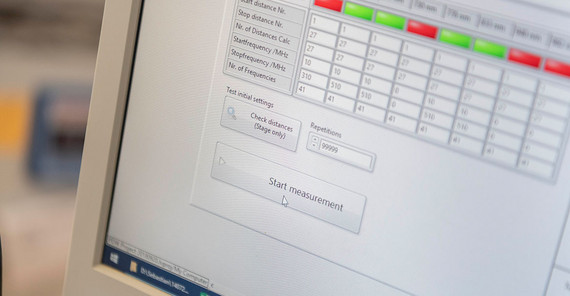

- Zimmermann configures the automatic synthesis program on the computer and starts it. The pH value is set at the start of the measurement with one milliliter of the water glass solution.

- The hoses for introducing the sulfuric acid and the water glass solution into the reactor are pre-rinsed so that no residual water distorts the measurement; then they are hooked into the reactor.

- While the chemicals are pumped into the reactor, Koenig takes a sample from the mixed solution every five minutes using a glass pipette. These samples are used for another method in the adjacent lab: dynamic light scattering to measure particle size distribution.

- The solution gels and its color changes to white. The researchers determine the viscosity increase point, a measure for the viscosity of the solution, by reading the relative torque, which reaches its highest value at that point.

- The synthesis is complete. The data from the measuring probe is analyzed and compared on the computer. Then the reactor with the solution is cooled down.

The Researchers

Sebastian Zimmermann works in the NanoPAT project and is doing his doctorate in physical chemistry.

Email: sebastian.zimmermannuuni-potsdampde

Aaron Justin Koenig works in the NanoPAT project and is doing his doctorate in physical chemistry.

Email: aaron.koeniguuni-potsdampde

The Project

The NanoPAT’s team consists of 16 partners from eight countries and is part of an EU project funded by Horizon 2020. It is developing three novel real-time nano-characterization Process Analytical Technologies (PATs) for the investigation of nanoparticle syntheses focusing on the in-situ application of the techniques/methods and direct links with participating industrial partners.

Participants: IRIS Technology Solutions, University of Potsdam, Medical University of Graz, POLYMAT, Zurich University of Applied Sciences, PDW Analytics GmbH, ANALISIS-DSC, Covestro AG, Evonik Industries AG, FLUIDINOVA, S.A., Arkema France, Creative Nano, TEMAS Solutions GmbH, Bio- NanoNet Forschungsgesellschaft mbH, EXELISIS PC, BRAVE Analytics GmbH

Funding: European Union / HORIZON 2020

Duration: 06/2020–06/2024

This text was published in the university magazine Portal Wissen - Eins 2024 „Bildung:digital“ (PDF).