The term is an oxymoron: synthetic biology. This field of research has been developing very rapidly for some years now, in which biologists, chemists, and engineers collaborate to create new organisms or molecules that do not exist in nature. Specific properties of an organism can be modularly transferred to another. Many people are skeptical or even frightened by this, but many examples illustrate how helpful and useful biotechnological research is for everyday life.

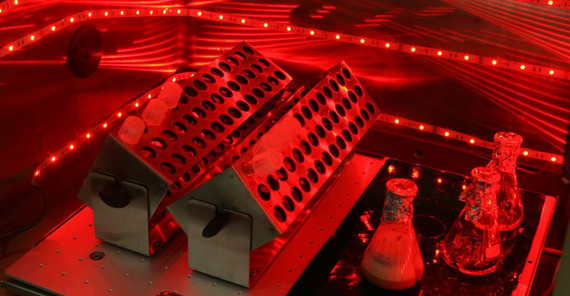

Katrin Messerschmidt opens the incubator door. A little flask with a cloudy liquid stands in an appliance reminiscent of an oversized microwave. Beside it is a rack of test tubes containing a yeast culture with millions of cells of ordinary baker’s yeast in a nutrient fluid. Aluminum foil shields the glass door. “So no outside light shines in,” the young researcher explains. Messerschmidt, a biochemist, grabs a remote control – and it starts getting colorful. Red, green, and blue – small chains of light begin to gleam on the incubator walls, which has a consistent temperature of 30°C. Messerschmidt adjusts the light color that shines on the yeast cultures with the remote control. “We still use simple party lights, but we will soon be installing diodes with a precisely defined wavelength,” the researcher says. She is working on a process she calls “light-induced protein production”.

Since April 2013 Messerschmidt has been the head of the junior research group “Cell2Fab” (acronym for “Synthetic Biosystems – From Cell to Fabrication”) at the chair Molecular Biology. Funded by the Federal Ministry of Education and Research, Cell2Fab consists of Messerschmidt, a postdoc researcher, a technical assistant, and two PhD students who develop new procedures that aim to make baker’s yeast cells into tiny factories.

Saccharomyces cerevisiae – the scientific name of baker’s yeast – has been used in biotechnology for decades to produce useful substances. For this purpose the genotype of yeast cells is modified. The hormone insulin, vital for diabetics and one of the oldest genetically engineered medications, is now mainly produced from yeast cells and bacteria. Insulin used to be tediously isolated from pig pancreas. Now that insulin can be biotechnologically synthesized the use of porcine insulin has become extremely rare.

The “Cell2Fab” researchers want to go a step further because cells have so far only been able to produce rather simple molecules with biotechnological methods. In addition to insulin, fat-dissolving enzymes in detergents and certain amino acids in animal feed are produced with genetically modified organisms. To produce each protein molecule, the respective genetic information of another organism has to be isolated, reproduced and incorporated into the target organism’s genetic material by using enzymes. The more information is needed and the more complex are the desired molecules, the more susceptible they are to disturbances. “The technology for quickly combining and introducing large numbers of varied genetic elements into a cell is still missing,” Messerschmidt explains. The junior research group wants to change this. “Our goal is to develop methods to rapidly clone specific genes, integrate them into the cells, and to temporally and spatially control the production in a cell,” the researcher says.

If simple organisms like yeasts end up being able to produce complex molecules, the potential applications – cancer medication, biofuels, vaccines, and even oil and plastic – would be far-reaching. Biotechnological methods also often conserve more resources and are much more cost-effective and faster than conventional production paths. Enriching bacteria and yeast with additional genetic information and cultivating them is relatively easy. Ultimately, the produced substances have only to be “harvested”.

One of the project’s challenges is changing the yeasts in such a way that they are able to produce the desired substances. The researchers also want to control production from the outside because allowing the modified cells to permanently synthesize a specific substance is not always desirable. The researchers are actually looking for an “on-off switch”. Here is where the party lights come into play again: The yeasts start producing protein when exposed to light of a specific wavelength; the protein synthesis stops when the light goes out.

The researchers copied this principle from nature. “Plants have to know whether it is day or night. They have proteins that change when exposed to light,” the biochemist explains. Only when exposed to light do the modified proteins change specific gene sequences in plant cells, which then trigger protein synthesis. The researchers now want to transfer this mechanism to yeast cells. “So far protein synthesis has been initiated by chemicals, for example,” Messerschmidt explains. This is an expensive and elaborate procedure.

Messerschmidt does not use the term “genetic engineering” when speaking about her work with friends. “When I tell them that I work with genetically modified organisms, their first reaction is “What?! Oh, dear!” she describes her experience, laughing. The term “genetic engineering” has a very negative connotation in Germany, Messerschmidt explains. Many people do not know that most diabetics use genetically engineered insulin. Now she often uses a little trick. “I say that I teach yeasts to produce drugs, for example. Then the people accept it.”

In addition to her scientific work Messerschmidt is also in charge of human resources, procuring work equipment and furnishing offices. “Science is sometimes really simple compared to all this,” she says tongue-in-cheek. She considers the practical relevance of the “Cell2Fab” research a key point. “We are working on something that combines basic and applied research and will ultimately solve problems.” And she plans on doing something really big. “If we succeed, we might soon be independent from oil. Cancer medication will not cost hundreds of thousands of euros but will be able to be produced much more cheaply. We want to combine naturally occurring substances so as to achieve the greatest benefit with very little effort.”

“Cell2Fab” has already found its first cooperation partner – the French National Institute for Agricultural Research (INRA) – to apply their research in the field of biological pesticides, but Messerschmidt remains tight-lipped about specifics. “A lot of exciting things are happening that we do not want to reveal too early,” she says and laughs.

Messerschmidt is aware of the limits of her research. “It is generally a great challenge in synthetic biology that we lack a 100-percent understanding of complex systems,” she says. Protein synthesis is a finely tuned system of genes, enzymes, and regulators influenced by countless individual factors. “Plants do not develop a biosynthetic pathway overnight. It has taken evolution several million years,” Messerschmidt underlines. “Can we implement such a fine regulation in a short period? Perhaps not in five years.”

The Researcher

Dr. Katrin Messerschmidt studied biochemistry in Potsdam and also wrote her dissertation at the University of Potsdam in 2008. Since April 2013 she has been the leader of the Junior Research Group “Synthetic Biosystems – From Cell to Fabrication” (Cell2Fab).

Contact

Universität Potsdam

Institut für Biochemie und Biologie

Karl-Liebknecht-Str. 24–25

14476 Potsdam

E-Mail: messeruuni-potsdampde

The Project

The Cell2Fab Junior Research Group researches the development of new methods to use the yeast Saccharomyces cerevisiae in biotechnological production. It receives funding as part of the strategic program “Nächste Generation biotechnologischer Verfahren – Biotechnologie 2020+” of the Federal Ministry of Education and Research.

Program period: 2013–2016, to be continued after evaluation until 2018

Text: Heike Kampe, Online-Editing: Agnes Bressa

Contact Us: onlineredaktionuuni-potsdampde